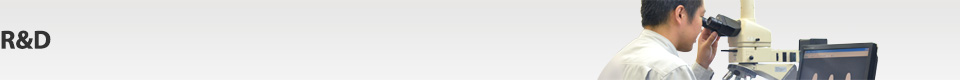

R&D Themes

“More efficient, higher-performance products,” “innovative materials” and “more sophisticated production technologies.” Together with existing core technologies, we strive to grasp future technological trends, combining technologies to create high-performance high-quality copper tube that meets customer needs.

- Combining copper with another metal to create copper alloy tubes offers improved characteristics, joining the exceptional workability of copper with increased strength and corrosion-resistance. KMCT strives to develop copper alloy tubes that anticipate the demands of the times, such as the shift towards natural refrigerants, and to be the first worldwide to achieve mass production. By developing thinner-walled copper tubes we are helping to resolve the issues faced by society and our customers.

- Inner-grooved copper tubes, which offer better thermal conductivity due to their subtle internal grooving, are widely used in air-conditioning heat exchangers. KMCT’s inner-grooved copper tubes help contribute to society by allowing machines to function more efficiently and reducing energy consumption.

- High-performance outer-finned tubes, which in addition to inner-grooving also feature complex outer molding, is mainly used in chillers. KMCT develops a variety of such heat exchanger tubes, which are tailored to individual machines and help improve performance for large-scale air-conditioning devices.

For years, phosphorus-deoxidized copper has been used for HVAC copper tubes. However, the environment surrounding copper tubing is currently undergoing big changes.

One such change is the shift, amidst growing concerns for the environment, from conventional CFCs, HFCs, and HCFCs to substitutes, including carbon dioxide (R744), a natural refrigerant. Compared to CFCs, carbon dioxide (R744) is utilized at a high working pressure, requiring that copper pipe walling be thicker and stronger. However, with the rising price of copper, in order to reduce the cost of HVAC equipment, tube made using a reduced amount of copper is desirable. Additionally, since copper tubes are used in a variety of operating environments, a high level of corrosion-resistance is required for tubes used in particular environments.

In order to meet these societal demands as quickly as possible, KMCT had focused on developing copper alloy tubes that anticipate the needs of the age. As a result we have been able to make headway in new technological fields, increasing the strength, heat-resistance and corrosion-resistance of copper tube by adding small amounts of other elements.

With successful development of a product that is thinner, lighter, and which shares in the same reliability and workability as phosphorus‐deoxidized copper, copper alloy tubes have become one of our chief products. Production of copper alloy tubes require sophisticated production technologies, but as industry trailblazers in the mass production of copper alloy tube we have lived up to customer expectations.

Copper alloys

| Alloy | Performance | Advantages | |

|---|---|---|---|

| High strength | MA5J (JISH3300C1565) | High strength | Strength is increased through the addition of a small amount of Cobalt precipitation hardening |

| KHRT (JISH3300C5010) | Heat resistance, high strength | Heat resistance and strength is increased through Tin solid solution hardening | |

| HRS35LT (JISH3300C1862) | Heat resistance, high strength | Heat resistance and strength is increased through Cobalt precipitation hardening | |

| Corrosion-resistant | Picoless | Pitting corrosion resistance Anti-scaling |

Protects against type II Pitting corrosion due to water (for type 1 Pitting corrosion G treatment insulated copper tube products are available) Protects against scaling |

| KALT | Ant-nest corrosion resistance | Effective against ant-nest corrosion caused by corrosive organic acids | |

Composition

| Alloy | Chemical composition (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cu | P | Co | Sn | Zr | Zn | Ni | Mn | |

| MA5J | 99.90 or more | 0.020 ~ 0.040 | 0.040 ~ 0.055 | - | - | - | - | - |

| KHRT | 99.20 or more | 0.015 ~ 0.040 | - | 0.58 ~ 0.72 | - | - | - | - |

| HRS35LT | 99.40 or more | 0.046 ~ 0.062 | 0.16 ~ 0.21 | 0.07 ~ 0.12 | - | 0.02 ~ 0.10 | 0.02 ~ 0.06 | - |

| Picoless | For details inquire directly. | |||||||

| KALT | For details inquire directly. | |||||||

- Contact: Hatano Plant Quality Assurance Section

- TEL: +81-463-82-2600

FAX: +81-463-82-7540